‘Leads and Lags’ is a technique of several processes in the area of Project Schedule Management according to PMI’s Guide to the Project Management Body of Knowledge (PMBOK®, 6th ed., ch. 6.3.2). They refer to the potential advance or delay of activities within a project schedule and are essential when it comes to scheduling activities on the project timeline (Source: Crandall, K: Project planning with precedence lead/lag factors, available in PMI’s Learning Library).

In this article, we are going to define both terms and provide an example of the practical use of leads and lags. Before you read this piece, make sure that you understand the concept of the Precedence Diagram Method (PDM) and their logical relationships first. If you need a quick refresher, read this article.

What is Lead?

The definition of ‘lead’ is that a successor activity is started before the predecessor activity has finished. For project managers to use a lead, the logical relationship between those activities must have been a discretionary finish-to-start or start-to-start dependency (as determined in the PDM).

Discretionary means that finish-to-start might be preferential, but it is not a hard logical dependency. In other words, there is no physical limitation or constraint that the predecessor needs to be finished before the successor activity can start.

If you are into baseball, you can think of it like this:

You may understand the concept of leading up face, you’ve heard of a run on leading up on the base, but what are they attempting to do? They are trying to shorten the time between two activities, right?

They want to get to that next piece as fast as they can before they are eligible or technically allowed to run fully, right? That’s the exact concept of a lead. It means you are going to accelerate a successor activity.

Using Lead Time in Scheduling Activities

Identifying lead times can enable project managers to (re)schedule activities to utilize that time. Thus, the earlier start of such successor activities compresses the overall time it takes to complete a sequence of activities (e.g. in a project or a work package).

For instance, let’s say we have two activities. One is going to take four days, and one is going to take five days to finish. That would be nine days total duration. Let’s assume the successor activity comes with a two-day lead.

This way, we can go ahead, make use of the lead time and start that successor activity two days before the predecessor has finished. Thus, the total duration is reduced from nine days, down to seven days.

In schedule network diagrams, lead is normally indicated with a negative number. It is negative because it is the time a project is saving compared to a finish-to-start scheduling. In our example, nine minus two gives us seven.

What Are Lags and Lag Time?

A lag is defined as a required delay in the start of the successor activity. Lag time is the number of hours, days, weeks (or any other unit of time) that has to pass while there are no resources associated with the successor activity during that time.

There are numerous reasons why lags are to be scheduled, e.g. due to physical or resource constraints, to wait for another activity to fully or partially finish or for certain dates and events to happen.

For instance, if you paint the walls in two days, the first coat (predecessor activity) needs to dry for a day or so. And then it is going to take you two days to do the next coat (successor activity). However, you cannot apply the second coat before the first coat has fully dried. You will have to wait for a day for the first coat to dry which is the lag time before you can start the successor activity.

All in all, the duration is two plus two days for the painting plus one day lag time between both coats. The total duration is five days although you would only be busy on four days.

In a network diagram, the lag would be indicated by a positive number because it is time that needs to be added.

What Are Leads and Lags Used For?

According to the PMBOK, ‘leads and lags’ is a technique that is used in the processes ‘sequence activities’, ‘develop schedule’ and ‘control schedule’ (PMBOK®, 6th ed., ch. 6.2, 6.5, 6.6). Leads and lags indicate the flexibility, or the lack thereof, when it comes to scheduling activities while taking logical relationships into account. Logical relationships are identified and prioritized using the precedence diagramming method, for instance.

Examples of the application of leads and lags are the schedule network analysis technique and the critical path method (source), as well as optimization strategies. These may include, for instance, schedule compression techniques such as fast-tracking.

Example of Leads and Lags in an IT Project

A typical finish-to-start relationship can be assumed for activities related to design, development, implementation, testing, and go-live of IT solutions. It looks like a ‘natural order of things’ that, as a first step, a solution is designed, then developed, then implemented, tested and eventually deployed.

In practice, however, projects tend to be constrained by tight timelines. If things go wrong part-way through the project, even compressing or crashing the schedule may be required. Being aware of the leads and lags of activities enables project managers to “save” project execution time.

Note that the activities of this example are aligned with those of the example of the use of the precedence diagramming method, so you can easily compare the uses of both techniques.

Durations and Dependencies

In a project, the durations are estimated as follows:

- technical design of module A: 10 days

- technical design of module B: 5 days

- development of module A: 15 days

- development of module B: 20 days

The dependencies are:

- the technical designs of module A and B, respectively, must be completed before the respective module can be developed,

- the technical design of module B makes reference to that of module A,

- thus, the module A design needs to be 50% completed before the module B design can be started, and

- the development of module A depends on module B, which needs to be 25% completed before the team can start the development of module A.

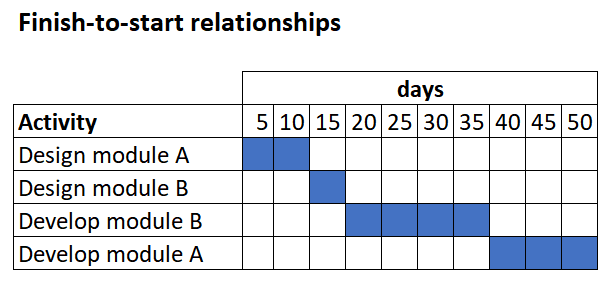

Finish-to-Start Sequence

Due to these interdependencies, a project manager could assume that there is an inherent finish-to-start relationship among these activities. If it were a sequence based on finish-to-start relationships, it would look as follows:

- Design module A

- Design module B

- Develop module B

- Develop module A

In this case, the combined duration of all 4 modules would be the sum of the activity durations, i.e. 50 days (10+5+20+15). This is shown in the below Gantt chart.

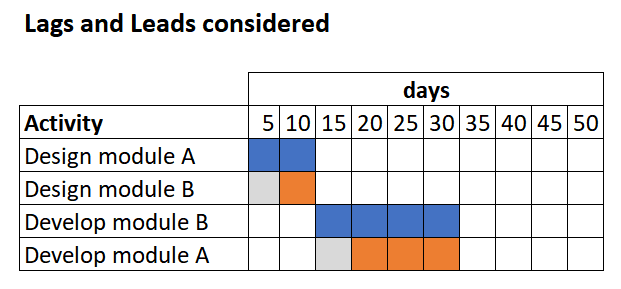

Sample Schedule with Lead and Lag Times

However, the descriptions give a hint that there are also leads and lags. These can be considered when planning the schedule:

| Activity | Dependencies and durations | Lag time | Lead time |

| Design module A | takes 10 days | first activity | first activity |

| Design module B | can start 5 days after the design of module A started and takes 5 days | 5 days (after start of A) | 5 days (before finishing A) |

| Develop module B | can start when the design of module B is completed and takes 20 days | no lag | no lead |

| Develop module A | can start when module B is 25% completed and takes 15 days | 5 days (after start of B) | 15 days (before completion of B) |

Refer to the below schedule diagram where leads are shown in orange and lags in gray.

Note that scheduling activities may also affect the resource and cost estimation of your project. In this example, you would likely have to increase the headcount if you intend to make use of the lead time.

Conclusion

A lead of a successor activity is represented as a negative number on a network diagram. Utilizing lead times when scheduling activities will accelerate the completion of a series of activities.

A lag is a necessary delay in the start of the successor activity that needs to be scheduled accordingly. It is shown with a positive number in a network diagram.

Lags and leads leverage flexibility in dependencies between activities that go beyond finish-to-start relationships. They are therefore essential techniques for proper and efficient scheduling of activities, the optimization of a schedule and as an input to determine a critical path.